We apply very stringent quality standards. In order to ensure consistently high quality products, we strictly enforce compliance to the internationally-recognized management system, such as ISO9001-2015, Kaizen and 5S. Compliance to stringent quality practices is expected to reduce wastage, ensure quality control, ensure proper maintenance of equipment and therefore reduce down-time due to machine problems. By enforcing compliance to standard operating procedures, the quality assurance is applied throughout the production process, starting from raw material purchase (100% checking of input materials in order to identify and eliminate defect products prior to production, and evaluating materials during the production in order to request the supplier to fix minor defects and to stabilize the raw material quality) to production of POY, DTY and FDY (quality assurance and quality control in production process in order to eliminate defect products) and warehouse management . We conduct 100% quality check for semi-products (POY) and finished products (DTY & FDY).

STK strictly enforce compliance to the internationally-recognized management system, such as ISO 9001- 2015, Kaizen, 5S, and Lean production.

Quality checking of POY before transferring to DTY workshop.

Quality control (knitting – dyeing – testing) in order to ensure quality before shipment to customers.

Quality control in Trang Bang 3 is also strengthened by application of Plant Operation Center (“POC”) provided by Oerlikon Barmag. The POC helps identifying and eliminating substandard products right in the production process.

Product certificates and quality controls

The ISO 9001:2015 is quality management system standard which is designed to help organizations ensure that they meet the needs of customers and other stakeholders while meeting statutory and regulatory requirements related to a product.

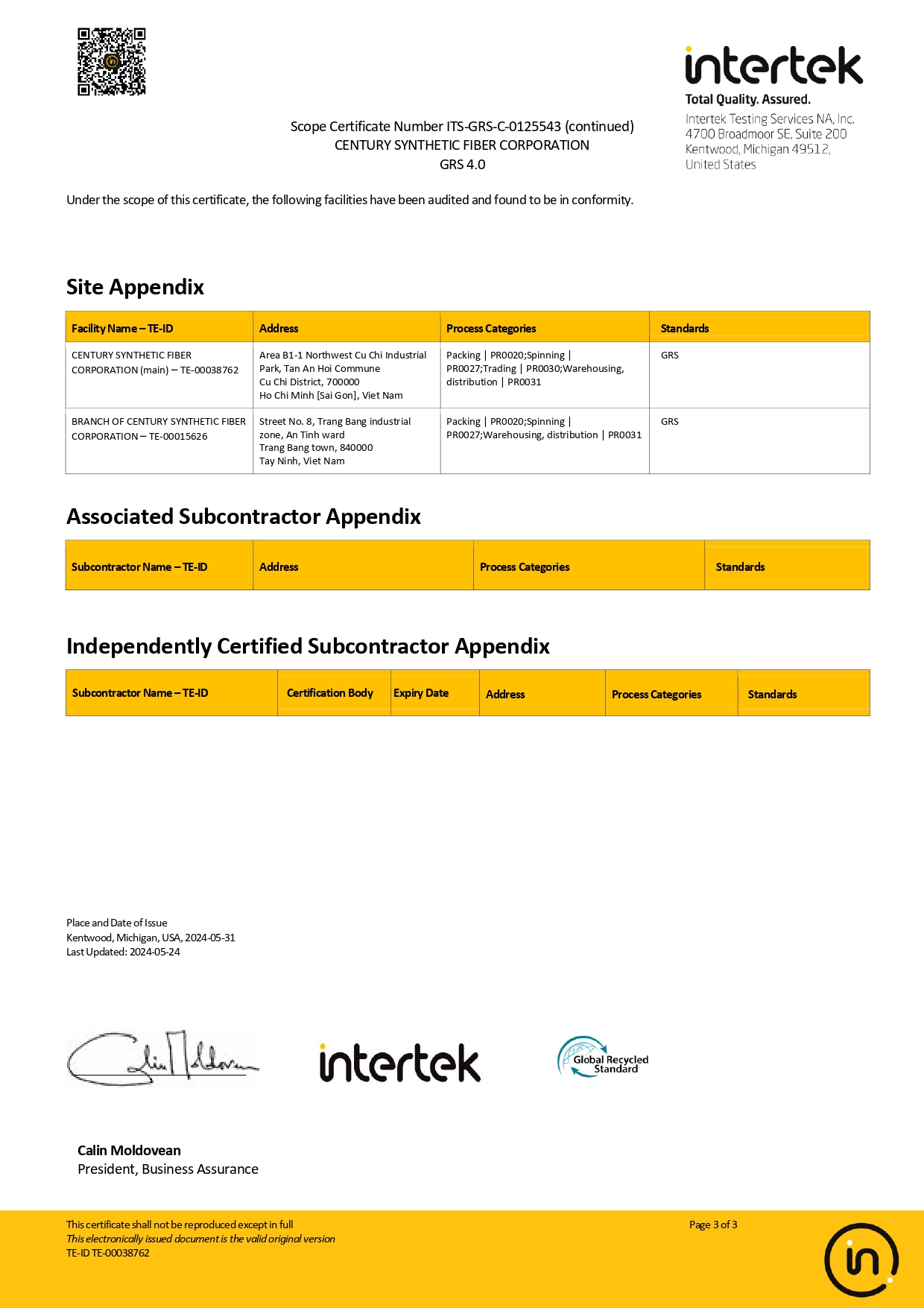

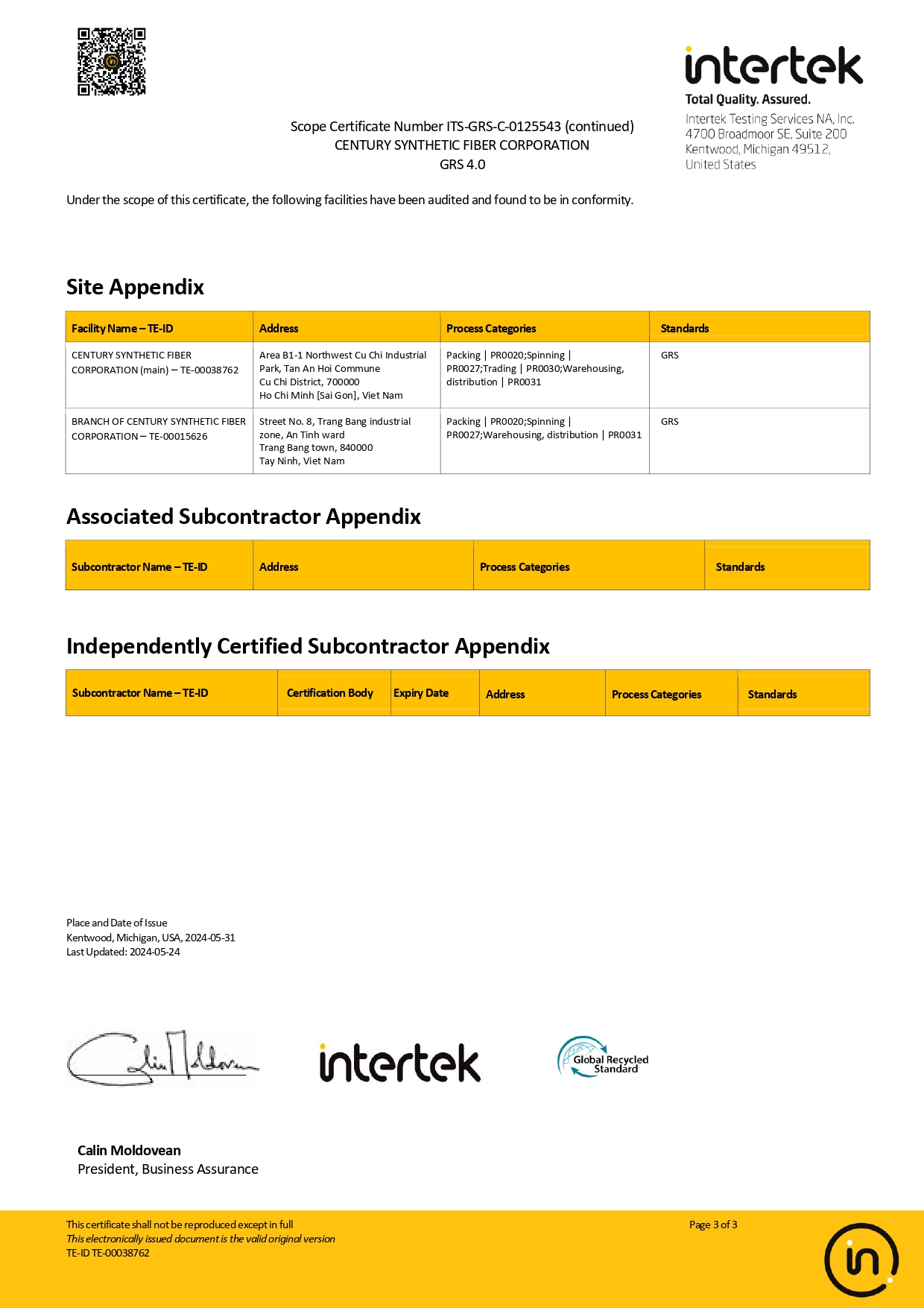

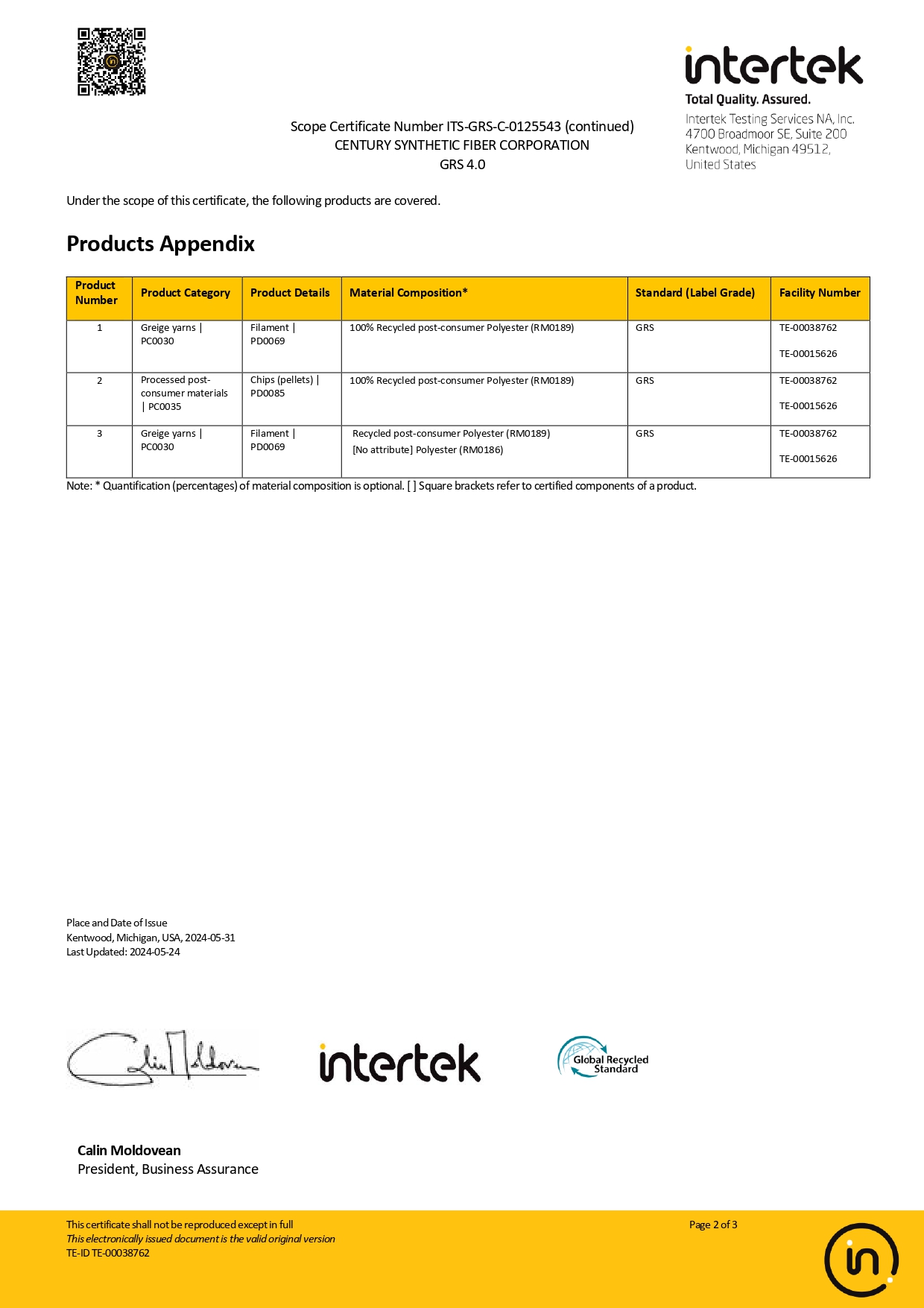

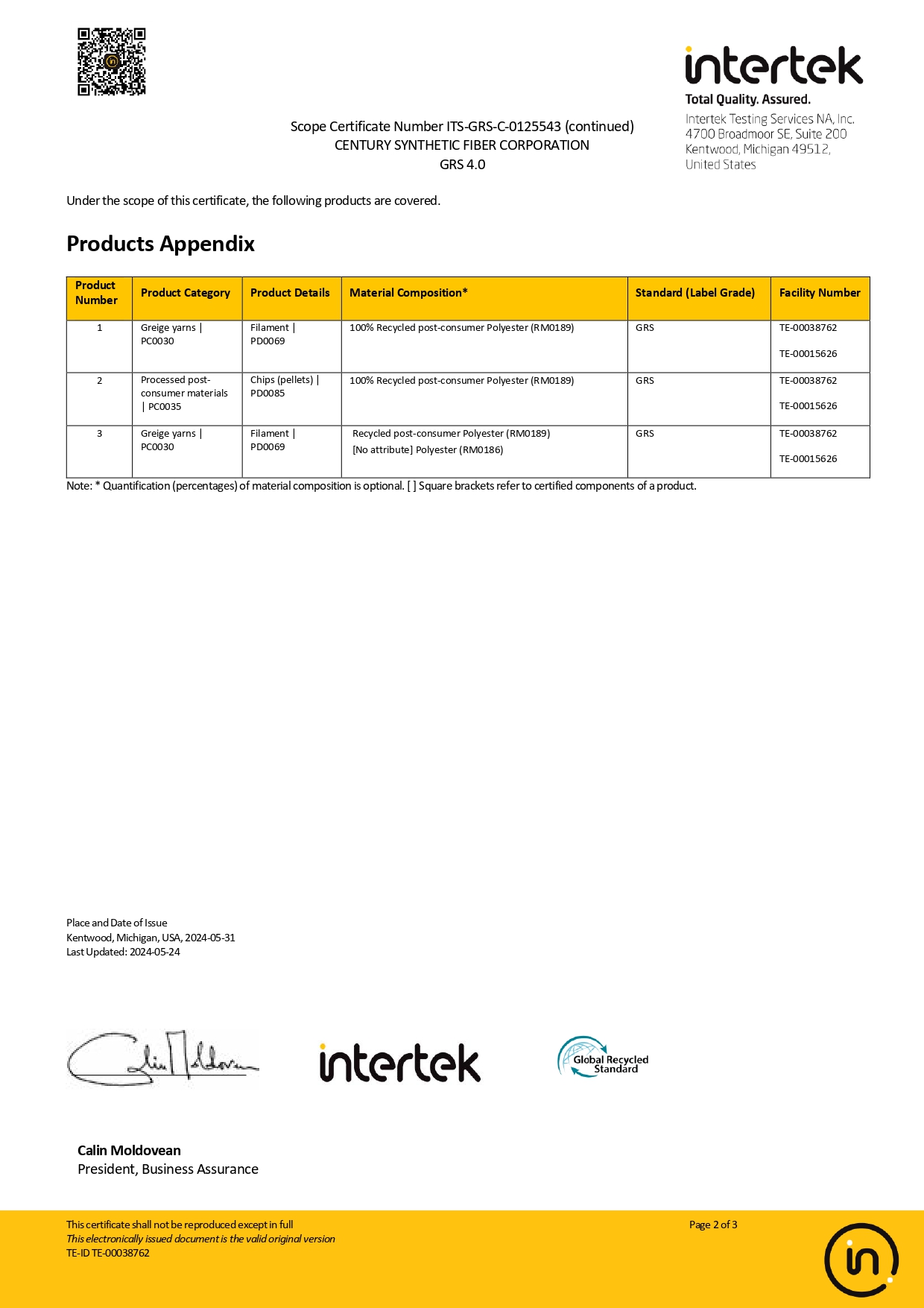

GRS – Global Recycled Standard – is a voluntary product standard that tracks and verifies the recycled material composition of final products. The GRS standard applies to the full supply chain and covers traceability, environmental principles, social requirements, chemical composition and labeling.

OEKO-TEX100 is the set of standards applied for testing and certification that textile product with this label do not use or remain below the set limit value for certain harmful substances (for instance: formaldehyde, heavy metal, pesticides, chlorinated phenol and phthalates).

All of the Company’s products DTY, POY, FDY have to comply with strict requirements of hazardous chemicals of REACH 168 regulation EC 1907/2006 issued by European Chemical Agency.

Registration, Evaluation, Authorisation and Restriction of Chemicals (“REACH”) is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals.

We apply very stringent quality standards. In order to ensure consistently high quality products, we strictly enforce compliance to the internationally-recognized management system, such as ISO9001-2015, Kaizen and 5S. Compliance to stringent quality practices is expected to reduce wastage, ensure quality control, ensure proper maintenance of equipment and therefore reduce down-time due to machine problems. By enforcing compliance to standard operating procedures, the quality assurance is applied throughout the production process, starting from raw material purchase (100% checking of input materials in order to identify and eliminate defect products prior to production, and evaluating materials during the production in order to request the supplier to fix minor defects and to stabilize the raw material quality) to production of POY, DTY and FDY (quality assurance and quality control in production process in order to eliminate defect products) and warehouse management . We conduct 100% quality check for semi-products (POY) and finished products (DTY & FDY).

STK strictly enforce compliance to the internationally-recognized management system, such as ISO 9001- 2015, Kaizen, 5S, and Lean production.

Quality checking of POY before transferring to DTY workshop.

Quality control (knitting – dyeing – testing) in order to ensure quality before shipment to customers.

Quality control in Trang Bang 3 is also strengthened by application of Plant Operation Center (“POC”) provided by Oerlikon Barmag. The POC helps identifying and eliminating substandard products right in the production process.

Products certificates and quality controls

The ISO 9001:2015 is quality management system standard which is designed to help organizations ensure that they meet the needs of customers and other stakeholders while meeting statutory and regulatory requirements related to a product.

GLOBAL RECYCLE STANDARD V4.0 (GRS) is a product standard for tracking and verifying the content of recycle materials in a final product, while ensuring strict production requirements.

OEKO-TEX100 is the set of standards applied for testing and certification that textile product with this label do not use or remain below the set limit value for certain harmful substances (for instance: formaldehyde, heavy metal, pesticides, chlorinated phenol and phthalates).

All of the Company’s products DTY, POY, FDY have to comply with strict requirements of hazardous chemicals of REACH 168 regulation EC 1907/2006 issued by European Chemical Agency.

Registration, Evaluation, Authorisation and Restriction of Chemicals (“REACH”) is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals.